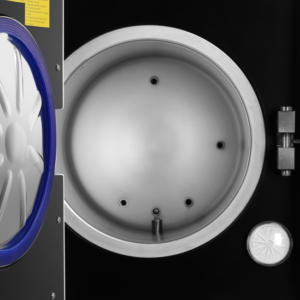

The 18-liter chamber allows for sterilizing a larger quantity of items in a single cycle, making it suitable for facilities with higher sterilization demands. These machines typically come equipped with user-friendly controls, safety features, and monitoring systems to ensure a reliable and safe sterilization process.

Advantages of an 18L High Pressure Autoclave for Dental Practices

The 18L high pressure autoclave dental solution offers a perfect balance of capacity, efficiency, and advanced features, making it ideal for dental clinics. Key advantages include:

Free OEM Logo

no screw design on the side walls, elegant and easy to disassemble

| Model | ECSS18 AD |

| Description | Small Autoclave |

| Class | B |

| Certification | ISO 13485 |

| Standard | BS EN 13060:2004 + A2:2010 |

| Frequency | 50Hz |

| Plug | 3 hole plug |

| Wattage | 1950 VA |

| Sterilization temperature | 105 – 134℃ |

| Max working pressure | 0.21-0.23MPA |

| Life span | 5 years |

| Diameter of chamber | 25 CM |

| Depth of chamber | 45 CM |

| Volume of chamber | 23L |

| Material of chamber | Stainless steel 304 |

| Colors available | White |

| Screen type | LCD |

| Screen size | 6 X 4.25 cm |

| Language available | English, French,Italian, German,Chinese |

| Lock system of door | Mechanic + electrical lockers |

| User password | Yes |

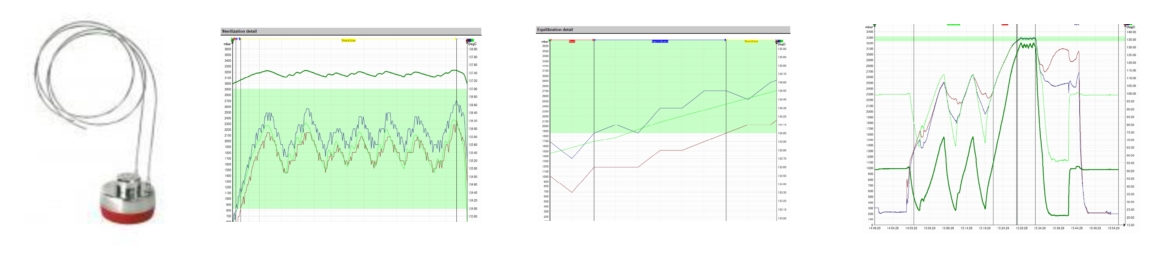

| Output | Thermo printer & USB |

| Net weight | 55 kgs |

| Gross weight / carton | 63 kgs |

| Product size | 65 X 50 X 43cm |

| Package size | 77 X 57 X 51cm |

| Min size of table for installation | 54 x 41.5 cm |

–The case can be opened widely makes the operation easily and safely.

–Easy for filling water and easy for clean.

–With water level sensor in both tank.

–0.2um filter and install in front easy for check and replacement

–front built-in printer easy for use

–Wiring and Piping are arranged neatly and reasonably which makes maintenance and repair a easy job.

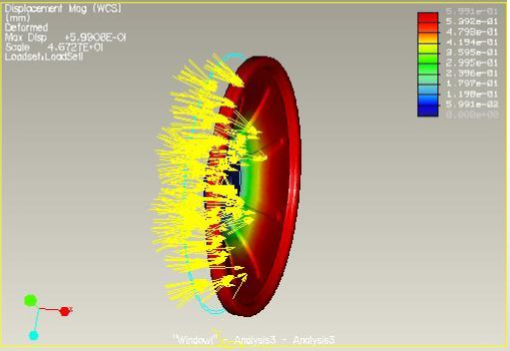

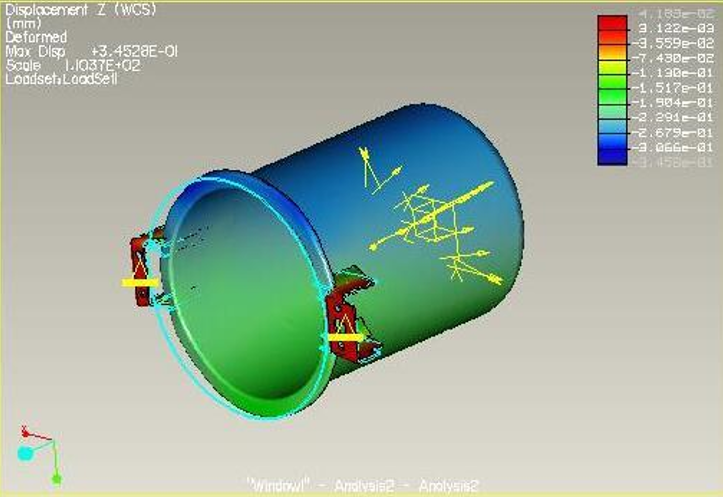

–The working pressure of dental autoclave is 2.1KG. And cycle time at most 30 thousand. The chamber we use which also reliable after 100 thousand pressure test(3KG).

–There is Pressure sensor on the PC board, it will adjust the pressure when the pressure more than 2.3KG. Also with safety valve at the back of autoclave. It will release the pressure when the pressure more than 2.4KG. Also we have a normal-open solenoid valve. When the power off during sterilization cycle, The valve will release the pressure in the chamber when the power off during sterilization cycle.

–Special design of sealing ring which can stand the test of 3KG pressure.

— latch with diameter 12cm; lock’s hook with two grooves.

Shut down the machine in case of electricity leakage or short circuit

Prevent the chamber from over pressure.

–The standard of this test is hold a certain vacuum pressure for more than 15min. During the period, the leakage is no more than 30kp. Our vacuum test including the above standard test and also we add time standard for our own vacuum test. So our test is finish the evacuation in certain time and the leakage is not more than 30kp in 15min.

–Test device is from Germany which can detect tiny difference of temperature and pressure automatically.

– Powerful & less noise

Same supplier with Melag, best Pump in the world

Built with SKG bearings Only we have SKG for this pump in China

–Solenoid valves and water Pump are from Parker OEM Supplier, with 3 years Warranty.

–Solenoid valves and water Pump are from Parker OEM Supplier.

–Copper pipe, withstand high temperature especially for the steam.

In medical and dental facilities, patient safety is paramount. By reliably sterilizing instruments and equipment, the autoclave helps prevent the transmission of infections and diseases, thereby safeguarding the well-being of patients.

Effective sterilization is a critical component of infection control. It plays a crucial role in reducing the risk of healthcare-associated infections, promoting a safer and healthier environment.

The larger chamber capacity of an 18L autoclave allows for the sterilization of a greater quantity of items in a single cycle. This improves operational efficiency by reducing the time and effort required for sterilization tasks.

By ensuring that instruments remain in a sterile condition, the autoclave helps extend their lifespan. This, in turn, reduces the need for frequent replacements, leading to cost savings for healthcare and laboratory facilities.

Healthcare facilities must adhere to strict regulatory standards and guidelines. An 18L autoclave can assist in meeting compliance requirements related to sterilization protocols, ensuring that facilities avoid penalties and maintain their reputation.

These autoclaves can accommodate a wide range of materials, including metal, glass, rubber, and plastics, making them versatile tools in various industries, from healthcare to research.

Smaller autoclaves might require more frequent cycles, leading to equipment downtime. With an 18L autoclave, downtime is minimized, ensuring a smoother workflow.

START YOUR PET WHEELCHAIR ONE-STOP PURCHASING JOURNEY

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you choose the right product solution

No. 1234, Lane 5678, Beauty Road, Pudong New District, Shanghai, China

START YOUR DENTAL MEDICAL INSTRUMENT ONE-STOP PURCHASING JOURNEY

START YOUR DENTAL MEDICAL INSTRUMENT ONE-STOP PURCHASING JOURNEY