Autoclave User Guide: Mastering the Correct Temperature and Pressure Settings

More worry free / Less effort / More competitive

In the dental office, proper sterilization is essential for patient safety and preventing cross contamination. Autoclaves use high-pressure, high-temperature steam to eliminate bacteria, viruses, and spores on dental instruments, making it the most effective and widely used sterilization method. But for best results, autoclave temperature and pressure settings must be precise. This guide covers:

1. Autoclave Basics: Why It Matters

Autoclaves utilize high-pressure steam to kill all microorganisms, including the most resilient spores, making them the “gold standard” for sterilizing dental instruments. The main advantages include:

- High Efficiency: Unlike chemical or UV methods, autoclaves kill all microorganisms.

- Regulatory Compliance: Meets CDC, FDA, CE, and ISO standards.

- Extended Instrument Life: Proper sterilization protects expensive dental tools.

How It Works:

- High-temperature steam penetrates instruments.

- Heat denatures microbial proteins, killing them.

- Specific temperature + pressure combinations are required to destroy spores.

| Parameter | Function |

|---|---|

| Steam | Transfers heat, ensures penetration |

| Temperature | Typically 121°C or 134°C |

| Pressure | Raises steam temperature (water boils at 100°C at sea level; pressure allows temperatures above 121°C) |

| Time | Ensures thorough microbial kill (varies by instrument type) |

Compared to other methods, autoclaves are the clear winner:

2. Optimal Temperature and Pressure Settings: 121°C vs 134°C

Autoclaves typically operate at two common temperatures:

- 121°C, 2.1 bar (Standard Cycle) is a common sterilization temperature: Suitable for most general instruments (tweezers, scissors, plastics). Sterilization time: 15-30 minutes.

- 134°C, 2.2-2.3 bar (Fast Cycle): Ideal for metal instruments (e.g., dental handpieces), surgical tools. Sterilization time: 3-5 minutes.

⚠️ Key Points:

- Lower temperatures = incomplete sterilization.

- Low pressure = inadequate steam penetration.

- High temperatures can damage heat-sensitive items (plastics, rubber).

Common instrument settings:

| Instrument Type | Temperature | Pressure | Time |

|---|---|---|---|

| General Instruments | 121°C | 2.1 bar | 15-30 minutes |

| Dental Handpieces, Metal Tools | 134°C | 2.2-2.3 bar | 3-5 minutes |

| Textiles, Rubber | 121°C | 2.1 bar | 20-30 minutes |

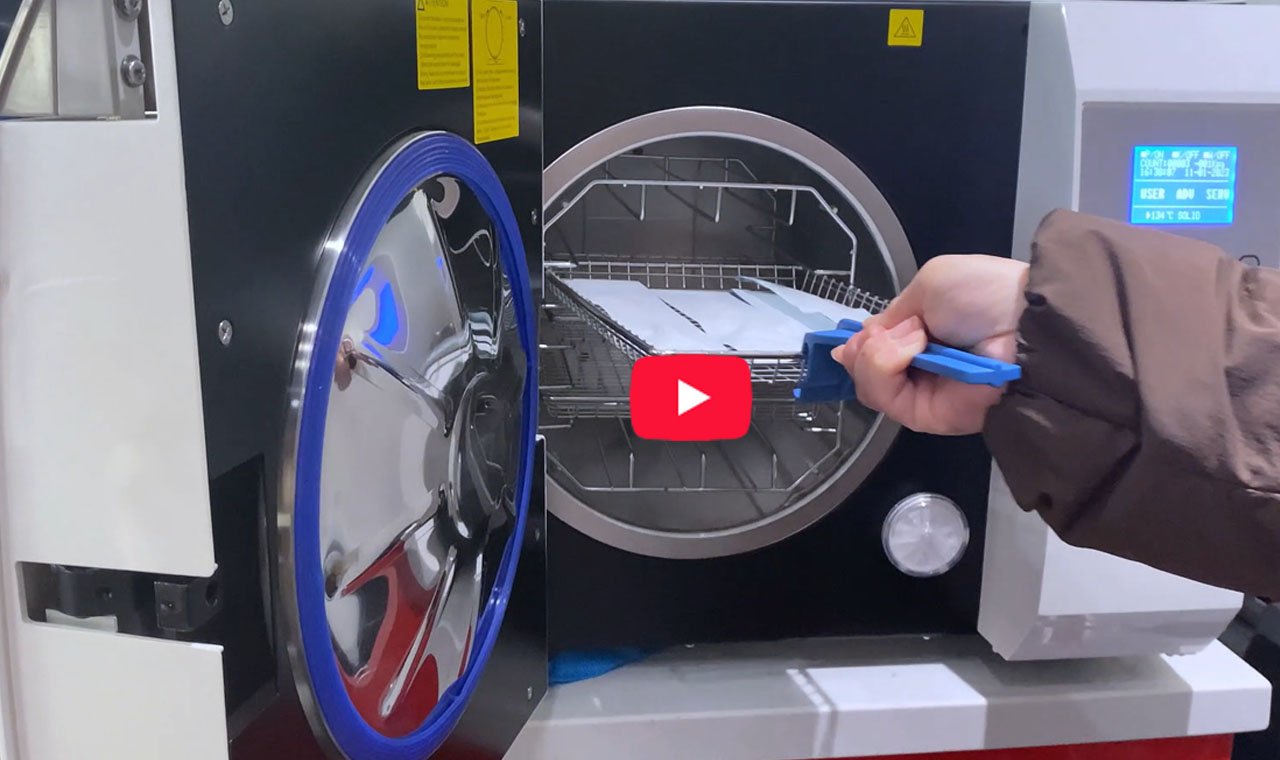

3. Step-by-Step Autoclave Operation

Step 1. Pre-loading Preparation (Critical)

- Ultrasonic cleaning removes biofilm and debris.

- Proper packaging in sterilization pouches (otherwise, instruments get re-contaminated).

- Do not overcrowd the chamber (steam circulation is crucial).

Step 2. Select the Right Cycle

- Choose based on instrument type: Standard (121°C) or Fast (134°C).

- Follow the manufacturer’s instructions.

Step 3. Monitor Key Parameters (Temperature, Pressure, Time)

- Check gauge readings for accuracy.

- Use chemical indicators (change color when sterilization conditions are met).

- Biological indicators (weekly/monthly spore tests to confirm killing of most resilient spores).

Step 4. Post-Sterilization Handling (Don’t Mess Up Here)

- Allow instruments to dry naturally inside the autoclave (don’t open the door prematurely).

- Store in sealed pouches or sterile cabinets, labeled with sterilization date (for traceability).

4. Troubleshooting Common Issues (Don't Wait Until Failure)

- Temperature Not Reached?

Might be overloading, faulty steam generator, or damaged sensor.

Solution: Reduce load, check steam source, calibrate sensor.

- Incorrect Pressure?

Low pressure = leaking door seal or blocked steam outlet; high pressure = faulty pressure relief valve.

Solution: Replace seals, clear outlet, repair valve.

- Sterilization Failure?

Check with indicators. If failed, isolate load, retest autoclave.

5. How to Choose a Reliable Autoclave (ESCO Example)

Don’t just look at the price; buy products with international certifications:

- CE Mark (EU safety standards).

- FDA Approval (US medical device clearance).

- ISO 13485 (global medical device quality management).

Types of Autoclaves:

- Gravity Displacement (simple instruments).

- Pre-vacuum (Class B) (complex/hollow instruments like dental handpieces; ESCO uses this technology).

At ESCO Dental Equipment, we understand the critical need for high-performance autoclaves in dental sterilization. Our autoclaves feature:

- CE and FDA Certifications → Ensuring compliance with global sterilization standards.

- Efficient Pre-vacuum Technology → Providing deep steam penetration for thorough sterilization.

- Reliable and Durable → Designed for long-term use in dental clinics worldwide and a robust distribution network.

Sterilizers are not “infallible” equipment. The synergistic effect of temperature, pressure, steam and time determines the quality of sterilization.

Mastering the loading adaptation temperature, precise pressure control and scientific loading can not only ensure the sterilization standard, but also extend the life of the equipment and reduce the failure rate.

Standardized operation + regular maintenance, your sterilization work will be “zero error, efficient”!

Whether you’re a dental professional or distributor, ESCO Dental Equipment offers state-of-the-art autoclave solutions to ensure thorough sterilization, patient safety, and compliance with industry standards. Contact us today for more information😊!

Related Dental Products

How Can We Help?

START YOUR DENTAL MEDICAL INSTRUMENT ONE-STOP PURCHASING JOURNEY