Modern dental medical equipment and instruments are striving to reduce patient discomfort and anxiety. For any dentist, managing dental clinic equipment is a significant step in their practice. Whether refurbishing an existing clinic or setting up a new one, it is essential to carefully and scientifically choose dental medical equipment and design an efficient, comfortable, and quiet environment. This approach will support the healthy development of the clinic.

Essential conditions for a dental clinic.

- The clinic should have treatment rooms, X-ray rooms, a sterilization room, a machine room, a consultation room, and a digital center.

- There should be adequate water and electricity supply. The water pressure entering the dental chair should be no less than 2 kilograms. Water pipes for general use and for the treatment rooms should be installed separately. Different working voltages should be provided to ensure the normal operation of all electrical equipment.

- The drainage system should be able to connect to a sewage treatment device.

Therapeutic room

- One dental chair should be placed in each treatment room.

- Reserve space for the dental chair’s floor box.

- Reserve space for water supply pipes, gas supply pipes, sewage pipes, VGA or USB data cable pipes, thick PVC negative pressure pipes, negative pressure signal lines, and power cables.

- When laying the pipes, pay attention to the following: Firstly, for compressed air, the pressure at the equipment’s inlet should be 5.0 – 7.0 kg/cm². Additionally, for vacuum pressure, ensure that the vacuum degree is no less than 85 mm/Hg, and the flow rate is no less than 135 L/min. Furthermore, the pressure for tap water should be 2.0 kg/cm². Moreover, the AC power supply must be 220V/50Hz, with a power rating of no less than 1.5 kVA. Finally, ensure that treatment rooms, X-ray rooms, and sterilization rooms have separate distribution boxes to avoid interference.

- Conduct pressure tests on the positive and negative pressure pipelines after laying the pipes.

Studio

- The most important aspect of X-ray room construction is to strictly adhere to national and local regulations. It is essential to ensure compliance with radiation protection standards.

- In this case, the CT room has a usable area of 5.46 square meters (national standard: not less than 5 square meters). The room measures 2.60 meters in length, 2.10 meters in width, and 2.6 meters in height. The walls are made of 12 cm thick red solid brick, with 3.0 cm Pb (lead) barium sulfate protective coating applied both inside and outside. The floor is 22 cm thick cast-in-place concrete with an additional 3 mm Pb barium sulfate protective coating. The ceiling is 12 cm thick cast-in-place concrete with 2.5 mm lead plate protection. The protective door is 200 cm high, 90 cm wide, and lined with 3 mm lead plate. The observation window is made of lead glass, measuring 40 cm high, 40 cm wide, and 15 mm thick. A mechanical exhaust fan is installed in the ceiling.

- In this case, the X-ray room has a usable area of 4.10 square meters (national standard: not less than 3 square meters). The room measures 2.60 meters in length, 1.60 meters in width, and 2.6 meters in height. The walls are made of 12 cm thick red solid brick, with 3.0 cm Pb barium sulfate protective coating applied both inside and outside. The floor is 22 cm thick cast-in-place concrete with an additional 3 mm Pb barium sulfate protective coating. The ceiling is 12 cm thick cast-in-place concrete with 2.5 mm lead plate protection. The protective door is 200 cm high, 80 cm wide, and lined with 3 mm lead plate. Use lead glass for the observation window, making it 40 cm high, 40 cm wide, and 15 mm thick. Install a mechanical exhaust fan in the ceiling.

- An indicator light must be placed outside the door. The light should be on when the room is in use and off when the room is not in use.

- There should be hooks for hanging protective clothing inside the room.

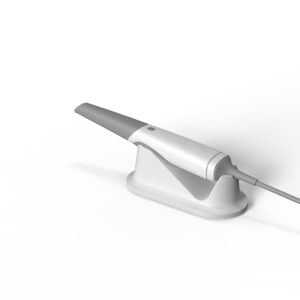

- The X-ray room should not have windows. For small X-ray units, choose between wall-mounted or chair-mounted based on actual conditions. If considering the use of imaging plate scanners and CBCT, ensure that the computer configuration is not too low.

Disinfection room

- The exterior should use transparent glass for full visibility.

- The room should have a one-way transfer window.

- Divide the sterilization room into a cleaning room, a packaging room, a sterilization room, and a storage room.

- Equip the cleaning room with an ultrasonic cleaner and a drying oven. If possible, add a medical cleaning machine to reduce workload and prevent sharp instrument injuries. Ensure the walls are smooth and even. Use wear-resistant, non-slip, corrosion-resistant, and easy-to-clean materials for the floor, but avoid materials that are too hard. Reserve space for water and air pipes (high-pressure water and air gun pipes) and water supply and drainage pipes.

- Equip the packaging room with a sealing machine, and recommend using an automatic sealing machine.It should be capable of printing seal time, expiration date, operator, batch number, and instrument name for traceability. Additionally, the room should have an oiling and maintenance machine, as well as equipment for instrument inspection.For the aseptic room, choose the sterilizer capacity based on the number of visits. Recommend a 45L sterilizer for daily sterilization needs. Reserve a power supply for the sterilizer, accommodating both 220V and 380V requirements. For the Blue Field 45L sterilizer, a 220V supply is sufficient. Ensure a side table is available for the sterilizer, with a socket placed on the table to facilitate connection.In the storage room, use a locker with an ultraviolet lamp. Position the locker 50cm from the ceiling, 20cm from the ground, and 5cm from the wall.

The computer room

- Configure both positive and negative pressure systems. Pay attention to the socket position. Connect the negative pressure pipeline to the sewage treatment device.Use water disinfection equipment and ensure separate systems for treatment room water and domestic water. Reserve two water sources to prevent equipment failure. Use tap water directly to supply the dental chair.Reserve the power supply and lay sewer pipes to facilitate equipment connection and wastewater discharge.